Thanks to our state-of-the-art glass curving machine at Specialist Glass Products, we can process curved glass units up to 3200mm in width and 5000mm in height. As a leading curved glass manufacturer, we have experience in many curved glass projects ranging from applications for curved glass windows, doors and balustrades.

Annealed Curved Glass

Annealed curved glass is achieved by applying heat to flat glass. This softens the sheet and allows us to shape it in a mould produced from a template or created from a Specialist Glass custom CAD drawing.

Curved annealed glass offers great design flexibility and can be produced from clear float glass, patterned glass, wired or tinted glass for different applications and design choices.

It can be used in single or double-glazed glass applications where safety is not a priority. Examples include upper-floor window glazing, clock faces, or picture frames.

Laminated Curved Glass

By applying an interlayer between two matching Annealed bends, we can create a laminated curved glass unit which is designed to withstand moderate impact.

Laminated curved glass is ideal for a number of applications, such as shop fronts, screens, glass partitions and canopies.

We offer a range of curved laminate glass, including SentryGlas®, curved glass or bespoke designs with cut-outs, notches or holes.

This glass can be used as components in double-glazed glass structures to add aesthetic benefits.

Toughened Curved Glass

Toughened glass is produced from annealed glass – which is heated and then cooled rapidly to strengthen it for enhanced safety.

It is designed to break into small, blunt fragments to reduce the risk of injury.

Popular applications for toughened glass are curved glass balustrades and curved glass doors.

All our toughened glass units are available in Low E, Low iron, tinted, painted and sandblasted. Heat soak testing and heat-strengthened glass is also available.

Our standout curved glass projects:

Curved glass solutions:

We can process and deliver curved glass in bespoke sizes for a range of applications, including:

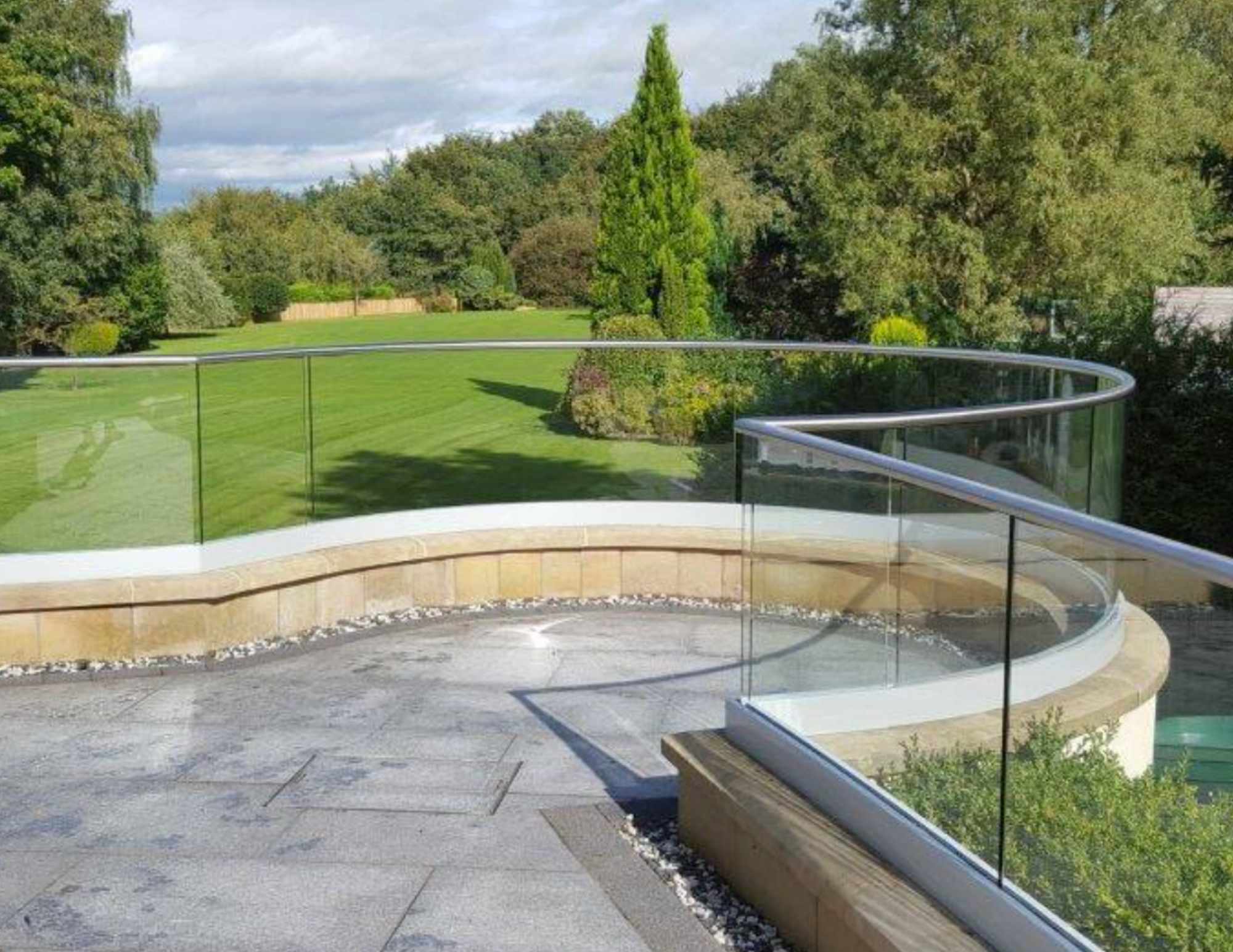

Curved glass balustrades

We process and deliver bespoke glass units for balustrades. Whether you are building a frameless curved glass balustrade, staircase balustrade or external balustrade, we can support you with choosing the most suitable glass.

Where safety is paramount or building regulations require it, we can process safety glass or toughened laminated glass for your project.

Curved glass doors

We can create toughened, laminated or curved safety glass units for internal and external doors. These can be customised with acoustic glass, fire rated glass, Low-U value glass or tinted glass to bring additional aesthetic or safety benefits.

Curved glass doors are suitable for a wide range of projects, including residential buildings, hospitality or office spaces.

Curved glass windows

We can process units for curved glass windows in sizes up to 3200mmx5000mm. We offer a selection of specialist materials, including tinted or energy-efficient glass to support internal comfort.

Why Choose Specialist Curved Glass?

Unmatched precision:

Our advanced glass bending technology ensures competitive precision when shaping curved glass, allowing us to create stunning and accurate glass units that set us ahead of the competition. Our meticulous control over the bending process guarantees consistent results that meet the highest industry standards.

Versatile applications:

Our curved glass opens up the possibility to various design opportunities, including toughened and laminated applications. Suitable for projects from architecture and construction to retail and interior design, our bespoke curved glass seamlessly integrates into projects, adding a touch of sophistication and uniqueness.

Aesthetic elegance:

As trends change over the years, the aesthetic appeal of curved glass remains. Whether used in modern building design, captivating showrooms, or commercial installations, our curved glass elevates the overall aesthetic of any environment. We can work with bespoke measurements to create stunning curved glass balustrades, curved glass doors, windows and more.

Customisation at its finest:

As an experienced curved glass supplier, we understand that every project is unique. Our glass bending machine empowers architects, designers, and builders to bring visions to life. We can tailor bowed glass in various dimensions and even the glass type to suit specific project requirements, offering a truly customised solution.

Cutting-edge technology:

Our glass bending machine, among an extensive range of technology, allows us to curve glass on such a large scale. We are proud to demonstrate our commitment to staying at the forefront of the curved glass innovation and providing our clients with the latest and most impressive offerings in the market.

Frequently asked questions about our bespoke curved glass:

How is curved glass made?

We process curved glass in two ways: modern and traditional.

Our modern glass manufacturing processes involve our bending furnace, which heats the glass so it can be easily bent into custom moulds. Our traditional technique is known as slump bending.

What are the benefits of curved glass?

Curved glass offers a variety of aesthetic benefits, and helps to create custom features in residential and commercial settings. Modern building design often features bowed glass as it can help to accentuate a building’s contours and create an interesting architectural feel without compromising on natural light.

How thick is curved glass?

The choice is yours! At Specialist Glass Products, we offer sizes between 4mm-19mm.

We would recommend thicker glass units for applications where safety is more important, whereas thinner units may be more budget friendly.

Can curved glass be double-glazed?

Yes, we can offer double-glazed and triple-glazed curved glass units. These can be fitted with specialist interlayers along with a warm edge spacer bar to support energy efficiency between the layers.

Is curved glass expensive?

As curved glass is processed using specialist equipment and skills, it is more expensive than traditional flat glass. Each bowed glass unit is unique, depending on the methods used, types of material or interlayer, and of course the size. Our team will guide you through the different options to find a curved glass unit which suits your budget best.

How to measure a curve for bespoke curved glass

At Specialist Glass Products, we ask for an MDF representation of your curved glass requirements, which you can sketch based on the size and curvature needed.

Then, we use our Proliner machine to sketch around the MDF shape. This sketch is transferred into a digital drawing that accurately measures your curve.

Alternatively, you can provide two measurements to help us draft a template for your approval.

Custom curved glass measurements and designs:

At Specialist Glass Products, our glass bending machine allows us to curve glass up to 3200mm x 5000mm in a range of thicknesses (4mm-19mm).

To enable Specialist Glass to manufacture a custom-made curve, we simply need two of five measurements along with the height, and any details about holes or patterns in the glass.

We offer competitive lead times on bespoke glass designs due to our new state-of-the-art systron proHD Vertical Glass Processing machine, which reduces our time spent polishing, washing and cutting pieces of glass.

The automated processes allow us to offer exceptional quality and can shape your glass units to virtually any shape, without compromising on lead times.

Whatever your specialist glass requirements, our team is here to help.

Let’s discuss your project today!