Toughened laminated units using SentryGlas® interlayer

We are proud to be certified to process toughened laminated glass units using the SentryGlas® interlayer produced by Kuraray. The specialised laminated glass interlayer was designed using an ionoplast polymer to meet the safety requirements of hurricane impact glazing and is 100 times stiffer than PVB interlayers.

The SentryGlas® interlayer brings many unique advantages to your project, including:

- Superior strength and durability,

- Improved UV resistance,

- Excellent tear resistance against attacks,

- Low yellow index for brilliant clarity.

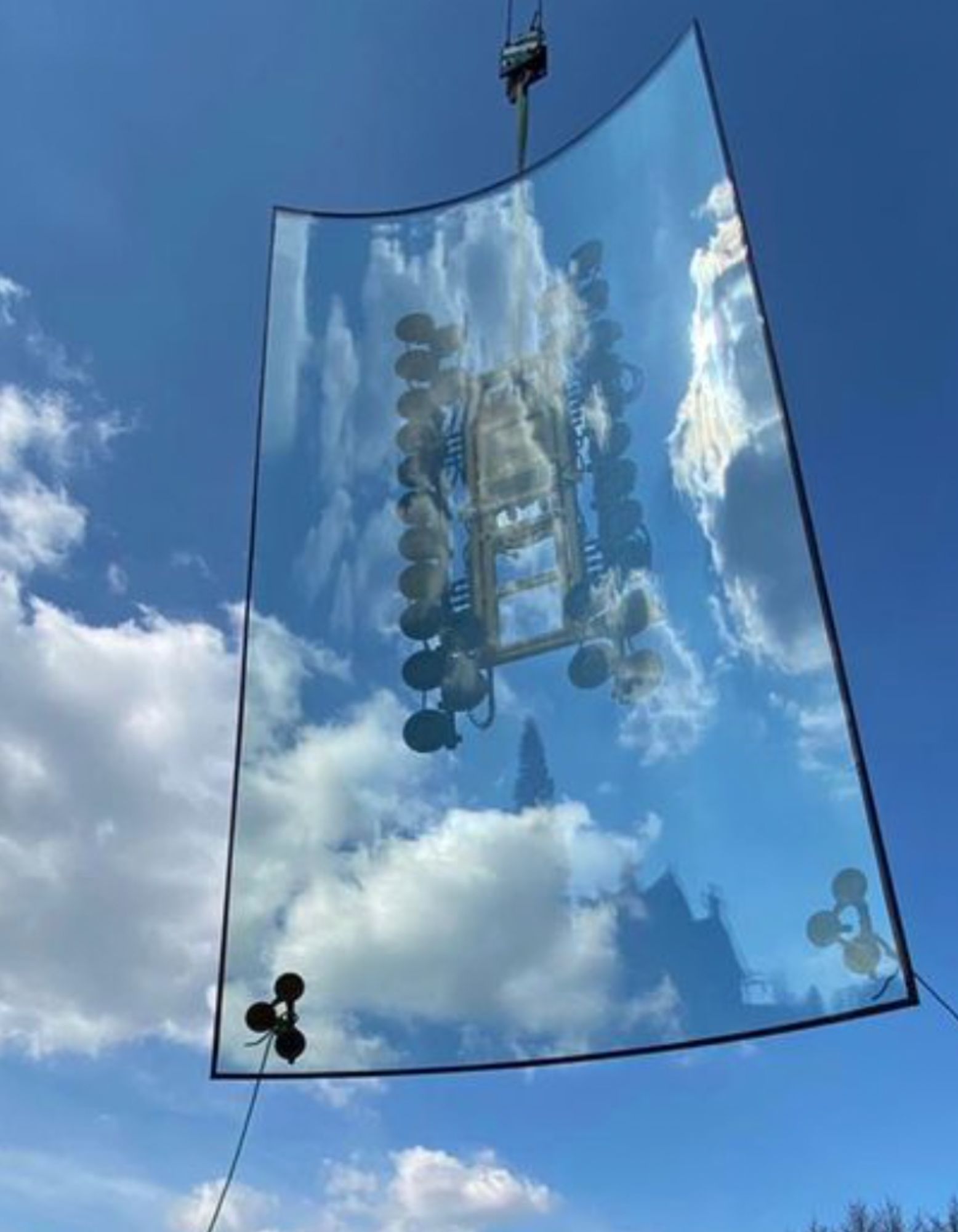

Suitable for a range of commercial designs, SentryGlas® is superior to standard laminated glass in its ability to keep occupants and customers safe, while being more resistant to breakages. For example, we supplied 28 Toughened laminated panels (2000mm x 1100mm 25.5mm) incorporating the SentryGlas® interlayer for an external laminated glass balustrade at a care home in York to enhance safety in this exposed outdoor space.

How are toughened laminated units made using the SentryGlas® interlayer?

During manufacture at Specialist Glass Products, glass units are first toughened, and then curved (if applicable), before being laminated with the SentryGlas® interlayer. We can offer glass units with the SentryGlas® laminated glass interlayer in bespoke measurements up to 5900 x 2500mm.