Toughened glass (also known as tempered glass) is a type of safety glass that undergoes controlled thermal or chemical treatments to enhance its strength and durability compared to standard glass.

Toughened glass is significantly stronger than annealed glass of the same thickness and can withstand higher impact forces, making it less likely to break upon impact.

When toughened glass does break, it shatters into small, relatively harmless fragments instead of large, sharp pieces, reducing the risk of injury.

Toughened glass has higher thermal resistance compared to regular glass. It can withstand rapid temperature changes without breaking, making it suitable for applications where temperature variations are common.

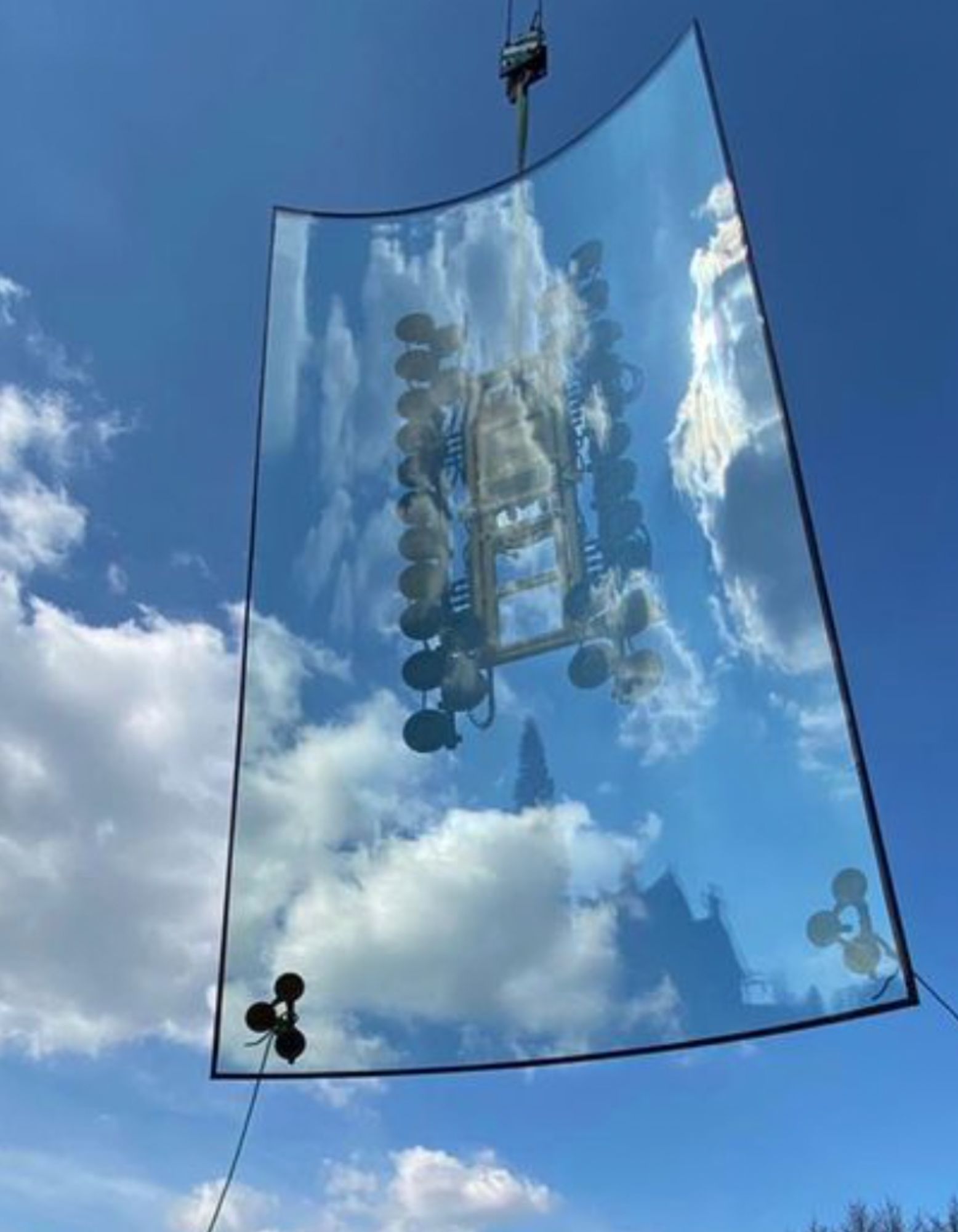

Toughened glass is widely used in various applications, including windows, doors, glass partitions, shower enclosures, glass furniture, and automotive applications (such as side windows and rear windshields). Its strength and safety features make it a preferred choice in areas where safety is a concern.

The tempering process involves heating the glass to around 620 degrees Celsius (1,148 degrees Fahrenheit) and then rapidly cooling it with forced air or jets of cool air. This creates a balance of surface compression and edge tension within the glass, enhancing its strength.

The tempering process induces surface compression on the glass, making it more resistant to scratches and other forms of damage.

Once toughened, the glass cannot be cut or altered, as any attempt to do so will cause it to shatter into small pieces. Therefore, any required shaping or cutting must be done before the tempering process.

Let’s discuss your project today!