With the demand for impressive structural glass in building design growing worldwide, manufacturers must invest in new and innovative machinery to keep up to date with the latest design trends. However, traditional ways to process glass remain crucial to the glass industry, allowing businesses to demonstrate their skill and create bespoke products and services.

At SGP, we value our high-tech manufacturing equipment just as much as our ability to process glass in traditional, tried-and-tested ways. Our entire collection of machinery and equipment allows us to complete orders to the most specific standards.

With this in mind, we have compiled a guide to some of our most utilised modern and traditional glass manufacturing methods:

Modern ways to process glass

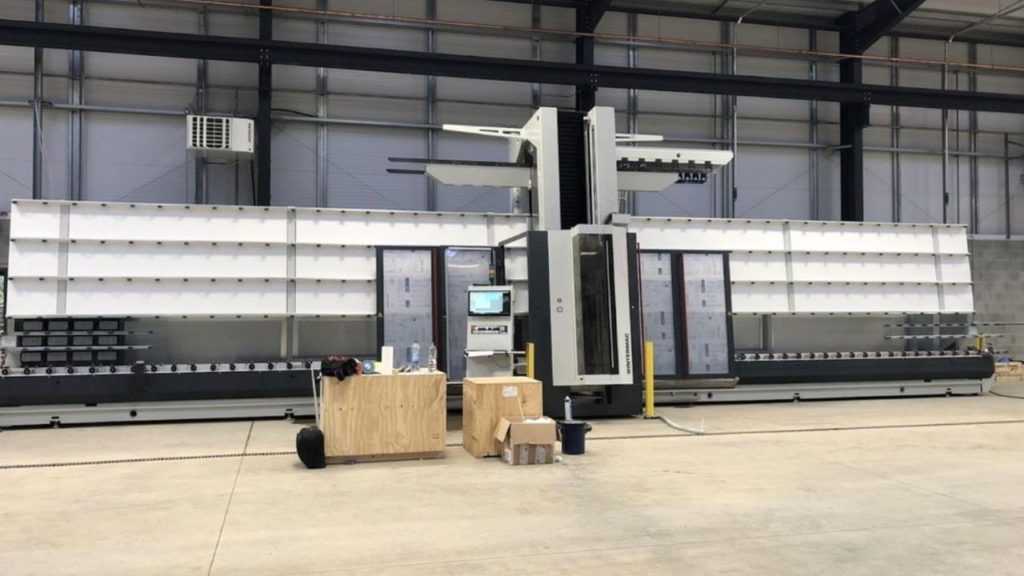

Vertmax CNC

Our Vertmax CNC (Computer Numerical Control) machine allows our team to polish and process complex shapes and cutouts in glass panels to meet our customer’s exact specifications. This machine can drill holes and process glass up to 6000mm x 2500mm, which is ideal for windows, glass doors and glass designs for commercial and domestic projects.

The computer controls allow us to process exact measurements and shapes within the glass, giving a much more accurate result when compared to traditional operator-controlled machines. Once we have set the specifications for the project, the CNC machine can quickly create accurate duplicates of glass units, which is ideal for projects such as glass staircases or glass balustrades.

Bending furnace

Our state-of-the-art bending furnace allows us to create custom curved glass for units up to 3200mm x 5000mm. Using the machine, we heat the product to soften it and bend the shape into custom moulds using the customers’ exact specifications. We can curve various materials using our bending furnace, from tinted glass, smart glass and self-cleaning glass, to suit various projects.

We slowly cool the hot glass after it has been bent to relieve any internal stresses and enhance its strength. For projects where glass needs to be even more durable, we can combine our curving capabilities with glass toughening or laminating to create a more robust material for increased safety, ideal for shop fronts or office windows.

Jumbo glass cutting tables

Our jumbo glass cutting tables are an invaluable modern addition to our factory, allowing us to cut large units up to 6000mm x 3210mm. This machinery is vital to our extra-large glass projects, such as large office windows, hotel balconies or architectural designs.

We also have large, modern racking for float and laminate glass to safely store our customer orders, ready to be sent across the country! The demand for jumbo glass units is always high among commercial customers, as glass is a highly stylish and versatile building material, so we place importance on having the equipment to process large panels.

Traditional methods to process glass

Plaster mould and slump bending

Unlike our bending furnace, traditional glass bending methods curve the glass without using a high-tech machine.

Slump bending involves using the heat of a kiln and the natural effects of gravity to bend flat glass using a mould. Once the glass takes the desired shape in the kiln, it is slowly cooled and brought back to room temperature to enhance its strength.

Plaster mould bending is performed by creating a mould out of plaster which reflects the desired angle of the glass bend, as given to us by the customer. This is a more gradual, gentle process compared to the speed of the glass-bending furnace, which requires no additional heat.

Hand polishing

While we value our modern polishing machines at SGP, our team is also experienced in hand polishing glass to get fantastic results. Glass polishing eliminates any imperfections created in the processing stage, such as scratches, scratches or pitting, to create a bright and shiny piece of glass.

Hand polishing is best for smaller, more intricate pieces of glass, such as our recent bevelled glass project, as we can ensure that the glass is treated with care and attention to detail. However, machine polishing is the best choice for larger projects such as jumbo glass units to achieve an even polishing effect, making the finishing process more efficient.

How does SGP decide on the glass process?

At SGP, we always use the best machine for the job due to our wide range of both modern and traditional tools in our factory. Our range of modern machinery is generally faster and more efficient than the older processes and can automate tasks such as duplicating a specific design.

Some machinery may be more suitable for a specific type of glass, which is when the older methods come in handy to ensure we can finish the job to the highest standard.

At Specialist Glass Products, having a variety of machinery and processes allows us to supply all types of products within the market, such as structural glass, curved glass and flat glass. Our wide variety of capabilities also allows us to offer express services to our customers, as we have many options to find the best possible route.

To discuss the use of glass in your next project, contact us today! Don’t forget to follow us on Instagram, Twitter, LinkedIn, and Facebook to view our latest projects and news.